Used Oil Refining

is a process technology and engineering company offering a wide range of oil & gas equipment’s and services for re-refining/recycling of waste/used lubricating oils.

Re-refining is the chemical process technology to recover the lubricating base oil from waste lubricants. Water, fuel oil, additives and sludge are separated from the base oil.

ChemSepT's technology for re-refining is based on vacuum distillation (using Wiped Film Evaporation). This is the most successful commercial method of re-refining.

What's more, ChemSepT's complete process treats used oil to produce base oil, which meets API Group II specifications.

ChemSepT Re-Refining Used Oil Process:

Used Lube Oil From Storage

Heavy Solids Removal(Sedimentation)

Dehydration

Defueling

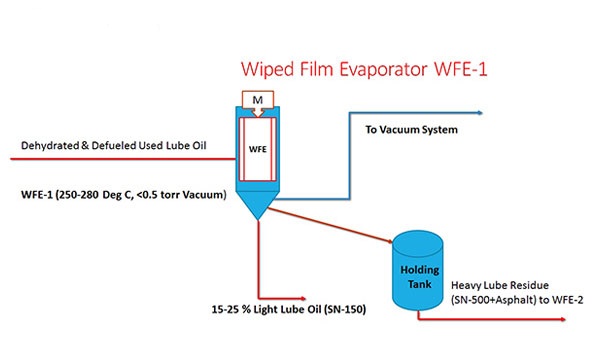

Seperation of Base Oil by Wiped Film Evaporator

Solvent Treatment (Color & Odour Improvement)

Used Oil Refining Process

Dehydration & Defueling

Step - I

Light Lube Oil Sepration (SN-150)

Step - II

Heavy Lube Oil Separation (SN-500)

Step - III

Product Load Outs

Step - IV

Re-refined Used Lube Oil & Solvent Extraction:

A liquid extraction process is done in the presence of solvent N-Methylpyrolidone (NMP).

The NMP is an aromatic selective solvent which removes some color and odor.

Also it is able to extract all unwanted aromatic contaminants present in lubricating oil fraction.